Active vs. Passive Heave Compensation

Active Heave Compensation (AHC)

Active heave compensation systems employ real-time sensors, control units, and powered actuators to actively counteract vessel motion. By continuously adjusting the lifting equipment to counter vertical displacement, they maintain the load’s position relative to the seabed or another vessel.

The benefits of AHC include:

- High positional accuracy in challenging sea states

- Extended operational windows, reducing weather downtime

- Especially valuable in offshore installations, where minimizing weather-related delays significantly reduces costs and emissions

Passive Heave Compensation (PHC)

Passive systems rely on mechanical elements such as gas springs combined with hydraulic damping to absorb and dampen wave-induced motion – without consuming external power.

Advantages include:

- Simplicity and reliability

- Lower cost and less complexity

- Ideal for budget-conscious operations

Safelink’s Market-Leading Solutions

Safelink supplies both active and passive heave compensation solutions, covering all phases of an offshore lift – from topside to subsea installations.

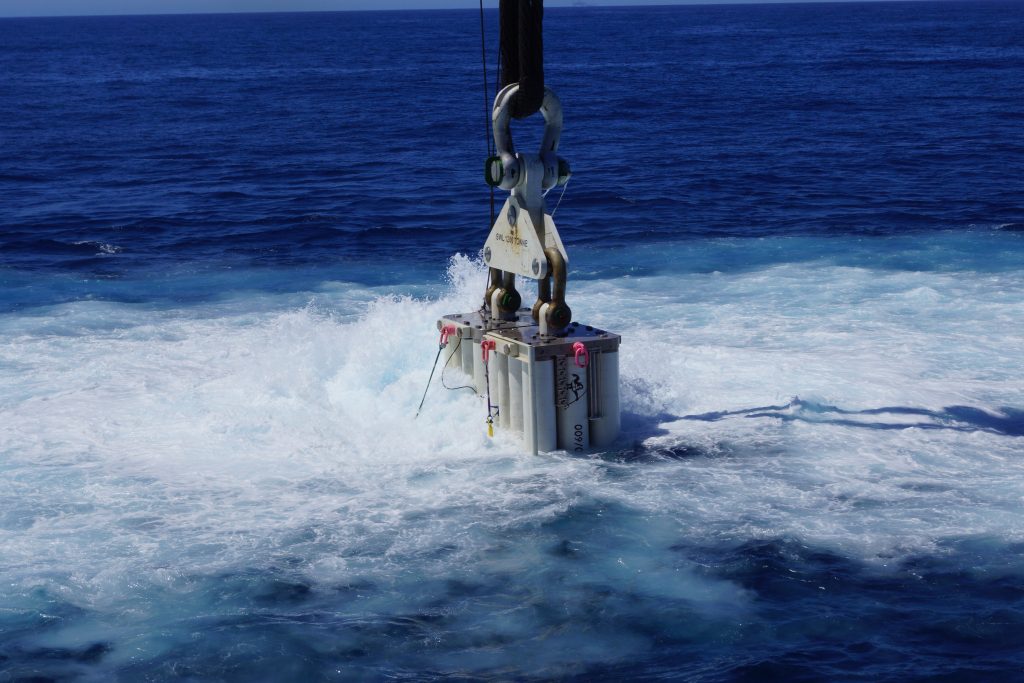

Passive Heave Compensators (PHC): The Poseidon Series

Safelink’s Poseidon passive heave compensators combine a gas spring and hydraulic damping to:

- Enable safer transitions through the splash zone and other challenges

- Reduce peak and fatigue loading

on crane and payload - Expand weather windows and provide flexibility between topside and subsea operations

The Poseidon series includes Standard PHC (plug-and-play) and Adaptive PHC (smart control features, subsea tuning, live data logging).

Inline Active Heave Compensators (IAHC): The Titan Series

Safelink’s Titan inline active heave compensator is a hook-based, self-contained, mobile system offering a high degree of flexibility without requiring permanent installation on a vessel.

Safelink’s Titan inline active heave compensator dramatically improves offshore wind lifting performance. By stabilizing lifts, the system expands operational limits – increasing uptime and reducing installation costs.

Why Heave Compensation Saves Time, Money and the Environment

- Increased Safety – reducing dynamic loading and protects equipment, personnel, and payloads

- Extended Operational Windows – operations can continue in rougher seas, cutting downtime

- Cost-Efficiency – smoother operations and reduced delays lower costs.

- Flexible Technology – from simple PHC to advanced AHC, Safelink delivers tailored solutions

- Vessel Emissions Reduction by reducing waiting-on-weather

Conclusion

Heave compensation is indispensable in modern offshore operations – facilitating safe, accurate, and cost-effective lifting in environments where wave motion threatens both success and safety.

As a full-spectrum provider of both passive and active heave compensators, Safelink delivers solutions that adapt to everything from simple splash-zone lifting to precise offshore wind turbine installations.